Hydraulics are increasingly trusted by many people to be used in machines and production lines in many industries, mining and life fields. So do you know what hydraulics is? Basic principles of hydraulic system and its advantages and disadvantages? Let's learn about hydraulics through the information below.

What is hydraulics?

The concept of what hydraulics is has long been no stranger to many people. Hydraulics is the movement as well as the force transport of a fluid in a confined medium. In a hydraulic environment, the fluid will be conveyed by thrust on the fluid.

Those liquids can be oil, viscous or chemical... with different viscosity, density, temperature, and properties. At present, hydraulics is widely applied in various fields such as: production lines of automobiles - motor vehicles, agricultural machinery production, wind turbines, mining, transportation, and product packaging. , wood industry and many applications in means of transport, construction...

Basic principles of hydraulics

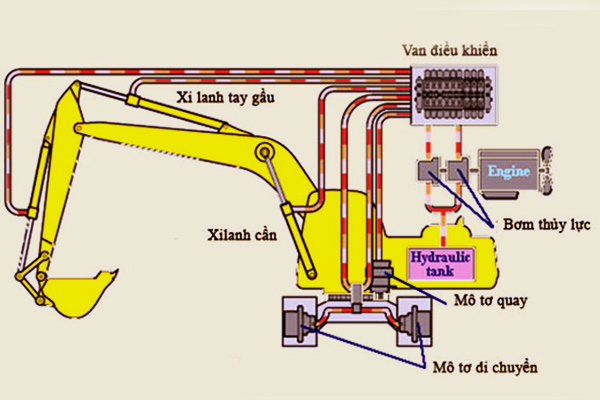

In hydraulic systems, oil acts as a medium to transmit force and also as a lubricant for the actuator and mechanism contact surfaces. Hydraulic oil when moving in the circuit has a closed and circulating nature, thanks to the hydraulic pump together with the control mechanism devices.

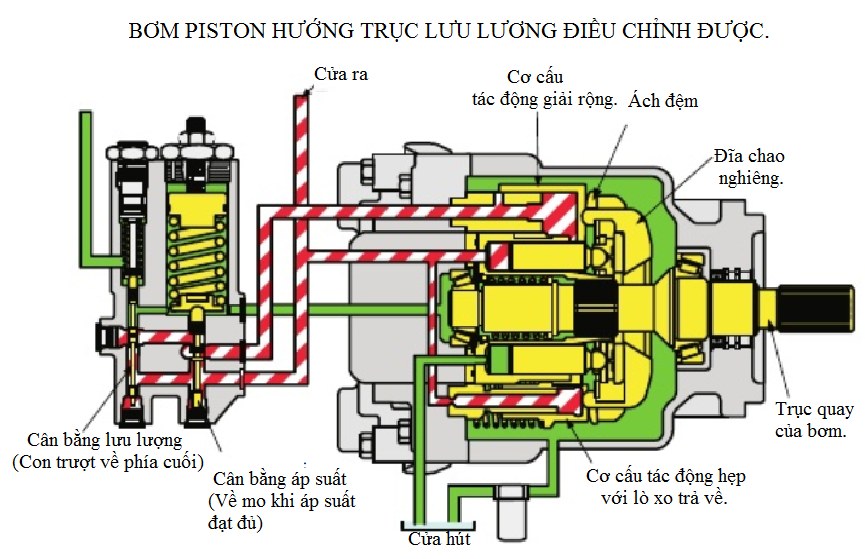

The most basic operating principle of the hydraulic system is to use an electric motor or a diesel motor to operate, pulling the oil pump to rotate. The pump will perform the suction of oil from the oil tank and push it to the mechanism in the system through the oil pipes. The pressure of the oil is controlled thanks to the safety valve to ensure the hydraulic system is always operating in the most stable way.

The hydraulic oil is directed to the control device and then to the actuator. Thanks to that flow, the pressure that the hydraulic pump creates, the reciprocating and rotating movements of the actuator. After transferring energy, the oil will be moved, returned to the tank and filtered back, cooled to continue performing a new process similar to the above.

Advantages and disadvantages of hydraulic system

Advantages:

+ The hydraulic system is selected to meet the purposes of using the transmission with large force and high power.

+ The hydraulic system has a structure with high safety, no need for meticulous maintenance.

+ Using hydraulic oil moving in the circuit is both the working fluid and the cooling, lubrication, and friction reduction, so maintenance is easy and less expensive.

+ The structure of the hydraulic system is simple, powerful, and neat

+ The speed adjustment and stepless or reverse adjustment are carried out more easily.

The system can be evaluated simply by building normalizations, and the conductive and driven components are not dependent on each other.

+ Quiet operation, low noise.

+ The hydraulic system is combined with a safety valve, so the ability to prevent overload is high.

+ The hydraulic pressure is monitored and checked by a pressure gauge. Barometer is easy even in complex systems, many devices, many different circuits.

+ The starting torque is relatively large.

+ Users can be proactive in reducing the size and volume of the system by choosing the pressure for the system.

Defect:

Once we have learned what a hydraulic system is, of course we all know that this system still has some disadvantages that need to be overcome and further improved:

- Due to the phenomenon of friction created and the leaks inside the elements of the pipe cause losses in the pipeline. The actuator as well as the system will inevitably reduce the efficiency of the mechanical system limiting the operating range.

- Air bubbles appear when starting to operate the machine. This is very easy to see with any machine or system.

- Oil in the hydraulic system has always played an important role. This amount of oil will be sucked up and moved in the hydraulic circuit and go to the structure, executing the task. Starting the hydraulic system will result in a sudden change in the temperature of the oil. This situation will lead to the working speed of the system, unstable cylinders, thereby affecting the working productivity of the entire system.