Today, there are many types of engines commonly used by people. Motors capable of converting electrical energy into mechanical energy are one of them. Especially brushless motor (abbreviated as BLDC) has high working efficiency as well as excellent controllability, so that it is widely used in many fields. Let's find out about Brushless Motors right through the article below!

What is a brushless motor?

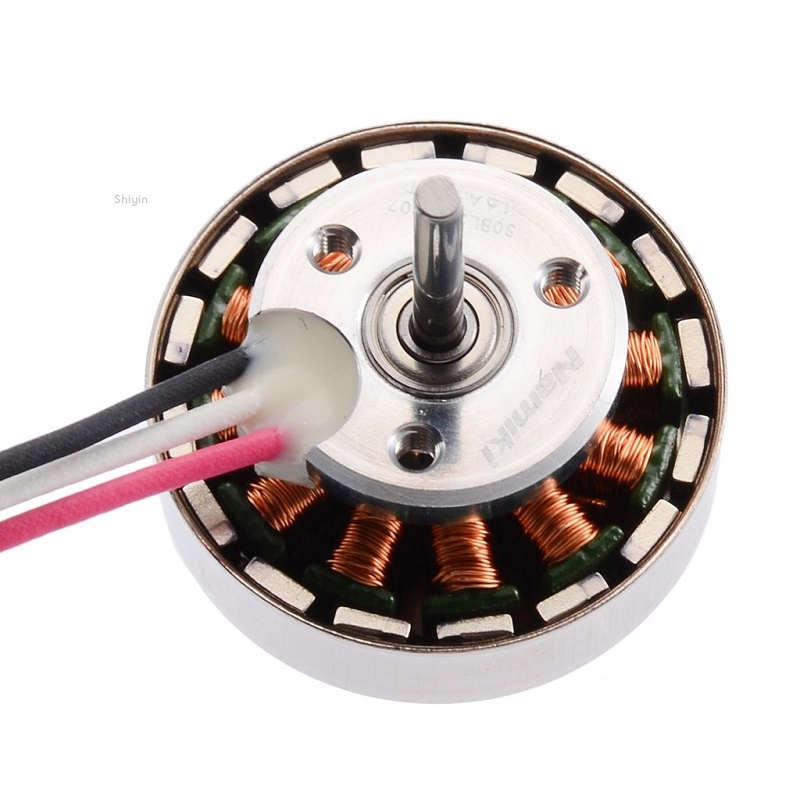

Brushless DC motor is a type of electric motor that is electronically switched with DC current electromagnets that move the rotor around the stator. The brushless motor is used with a controller to generate the conversion of electrical energy into mechanical energy.

The BLDC motor is a synchronous motor, that is, the rotor speed is equal to the magnetic field speed. BLDC motors are commonly used in printing, auto industry, automotive, medical and instrumentation applications.

Structure of brushless DC motor

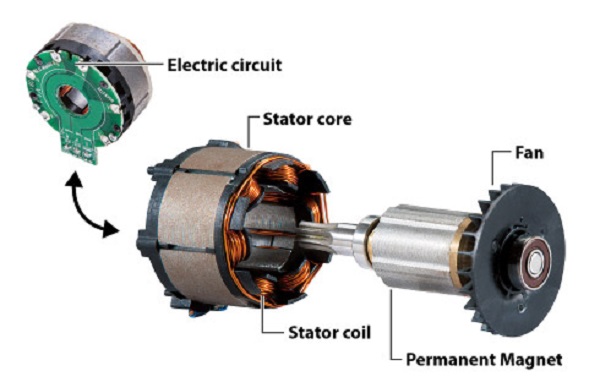

The structure of brushless DC motor includes:

– Stator: Consists of iron cores (electrical engineering steel sheets are insulated together) and windings. The winding of the brushless motor is different from the winding of a conventional 3-phase AC motor.

– Rotor: Rotor is similar to other permanent magnet motors.

– Hall sensor: Because of the characteristics of the electromotive force of the BLDC motor, it has a trapezoidal shape, so its normal control configuration also requires a sensor to determine the position of the rotor magnetic field in relation to the phases of the BLDC motor. stator windings. To achieve this, people often use Hall effect sensors, which can be called Hall sensors for short.

Brushless motor pros and cons

Advantage

– Efficiency: Brushless motors can be driven continuously while at maximum rotational force (also known as torque). In contrast, brush motors will achieve maximum torque only at certain points within the rotation. This is also the reason why even mini brushless motors can provide significant power.

– Good control of its operation: Brushless motor has controllability, using feedback mechanism to accurately distribute torque and rotation speed desired by the user. Precise control reduces energy consumption and generates less heat, if this is a battery powered motor it also helps to prolong battery life and durability.

The BLDC motor is also considered a highly durable motor and produces little electrical noise because it has no brushes. Brushed motors will wear out the brush and commutator because they are in constant, frequent motion and generate sparks and heat at the point of contact.

In particular, electrical noise will often appear in the areas where the brush passes through the openings inside the commutator. This also explains why Brushless motors are generally considered more suitable for applications where electrical interference is required.

Defect

The price of this product is a bit high because the Brushless Motor is made from permanent magnets and Hall sensors to control the motor speed and torque precisely. However, with the increasing trend of using brushless motors, the price also tends to increase.

Application of brushless motor

Some applications such as:

– Application of load in variable: Used in household appliances, Dryer, air compressor.

Location of applications: Industrial control and automatic control applications.

Brushless motors are also being used to operate the vacuum cleaner. In some cases, a change in the control program setting will lead to a major breakthrough in rotational speed. This is an example of the first-order controllability of these motors.

Brushless motors are also used to spin hard drives. Because of their durability, the drive will last longer for a long time. At the same time, the energy efficiency of the engine also contributes to reducing energy consumption.

Hope the above article has helped you understand what BLDC motor is. If you have any questions or need to use it, please contact Cuatudonganhkhoa.com for advice and a specific quote today!

CONTACT INFO

206/22 Dong Den, Ward 14, Tan Binh District, Ho Chi Minh

090 458 7544

anhkhoa.automaticsystem@gmail.com